Compactor Swap: EcoCentral’s Journey with Carbon Reduction

WRITTEN BY KATE GISLASON – SUSTAINABILITY ENGAGEMENT LEAD

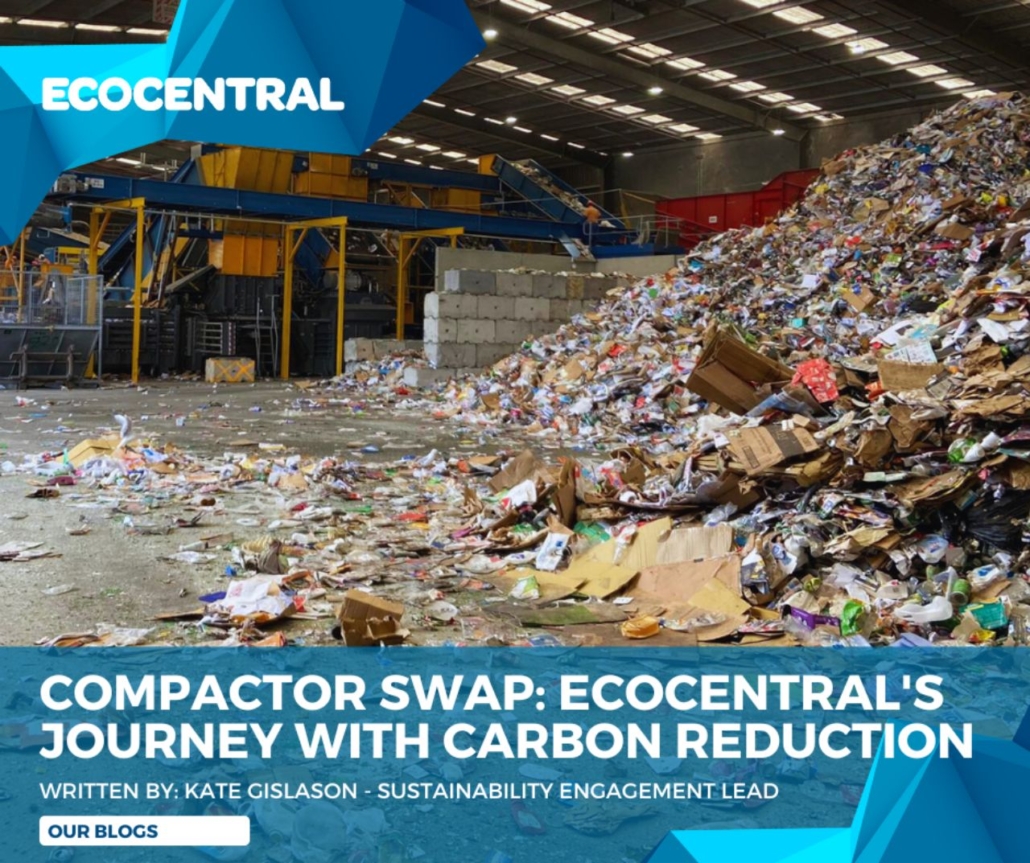

At EcoCentral, we’re committed to driving sustainability and reducing our carbon footprint. Over the past two years, our recycling sorting facility, EcoSort, has implemented significant changes that underscore this commitment. One of our most impactful initiatives has been the replacement of open-topped hook bins with compactors—a move that has drastically cut down our CO2 emissions.

At EcoCentral, we’re committed to driving sustainability and reducing our carbon footprint. Over the past two years, our recycling sorting facility, EcoSort, has implemented significant changes that underscore this commitment. One of our most impactful initiatives has been the replacement of open-topped hook bins with compactors—a move that has drastically cut down our CO2 emissions.

The Old Way: Open-Topped Hook Bins

For 15 years, our Materials Recovery Facility (MRF) relied on open-topped hook bins for waste collection. While these bins were functional, they came with significant environmental costs. The constant need to reposition bins with forklifts and their frequent emptying resulted in a high carbon footprint. Each bin emitted a staggering 45kg of CO2 every day due to this repositioning.

The New Way: Compactor Bins

In our search for a more sustainable solution, we introduced compactor bins. This change has proven to be a game-changer for our waste collection process.

With compactor bins, we only need to empty one bin daily. The new system has eliminated the need for continuous forklift repositioning. The impact: a 98% reduction in CO2 emissions. The results of this switch are nothing short of remarkable. By moving to compactor bins, we’ve managed to shrink our carbon footprint for this activity by an astounding 98%. This reduction is a testament to our ongoing efforts to implement sustainable practices and technologies at EcoSort.

At EcoCentral, we’re proud of the strides we’ve made in sustainability, specifically with carbon reduction. The success of our compactor swap initiative is just one example of how we’re working to reduce our environmental impact. We remain dedicated to finding innovative ways to enhance our recycling processes and contribute to a future we can be proud of.